Romak logistic, the largest product preparation terminal

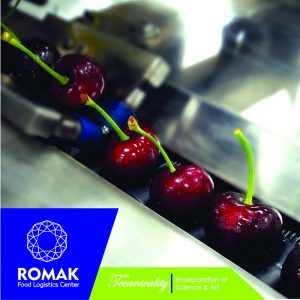

Romak export terminal, first, select the areas that are prone to growing the crop,then monitor its holding, harvesting and sorting, in order to provide high quality product and horticultural products .

considered product, after harvesting enters the plant and depending on its type, washing and cooling measures are taken before entering the refrigerator.